services

Optical/Mechanical Procurement

OSE Technical Procurement

Our motivation behind the origin of OSE has always been to simplify technical sourcing for our clients. Our team handles the procurement of precision optics, opto-mechanics, CNC-machined components, and complex cable-assemblies. OSE focuses a tremendous effort on locating the desired component in a complex and global marketspace.

These requests can include an improvement on quality, lead-time, cost or a first-time source of an unfamiliar product. Once procured, these components are screened using our optical and mechanical metrology laboratories at our facility to ensure the quality is met before it arrives at your company.

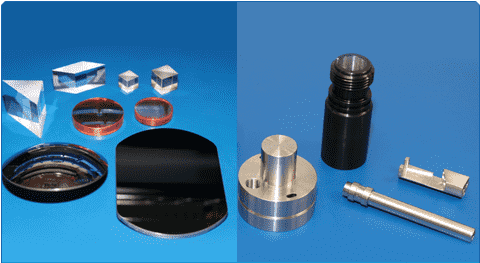

Optical Sourcing

Have our skilled optical engineers assist in procuring the optical components per your technical drawings. At OSE, the procurement team has an engineering background to ensure that the sourcing efforts are made with an eye for technical detail.

OSE can help your team with a range optical procurement requests including precision windows, lenses, doublets, filters, and even specialized optical coatings.

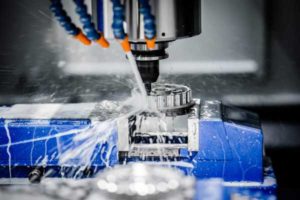

Mechanical Sourcing

OSE has a foundational strength in machined components for precision assemblies. Decades of experience working with high-precision machine shops for military components provides OSE with a uniquely clear view of machine shops. This has led to strategic partnerships with superior machine shops to leverage advanced capabilities, seasoned experience, and next-generation equipment for the perfect solution depending on the need.

Our machining partners work regularly with +/- 0.0001” tolerances and are well grounded in the areas of MIG, TIG, and Spot Welding. Depending on the application our partners in New England can provide 5-Axis CNC Milling, and mill and turn up to 8 axis. If larger parts are needed our team is capable of turning up to 53” Diameter parts and are well equipped to perform surface grinding, cylindrical grinding, and gun drilling. Our strategic partners in the Mid-West provide Wire EDM capabilities accurate to +/- 0.0003” with a grinding finish and have the capability to mil parts with up to 30” x 16” x 20” of travel.

All incoming work has full metrology performed at our facility in New England as a second check before it arrives at the customer site to guarantee the quality. The Wilmington-headquarters includes Mitutoyo drop indicators (NIST-calibrated), thread gauges, high precision gauge pins which are all utilized by a dedicated mechanical inspector and machinist with over 4 decades of experience. At OSE, we are here to ensure that your mechanical parts come in on time and in specification with no questions asked, and we leverage our strategic partners to ensure the right machine shop manufactures the component that fits their strength.

Supply Chain Management

Most technical companies understand the strength of their manufacturing floor starts with a well-run inventory and sourcing team. Our philosophy at OSE is to ease your manufacturing burden by providing quality components in a timely fashion. Our services range from inventory control at our facility just outside of Boston, to AQL-based quality inspection and Kanban systems to reduce the cost of inventory at your site. On-time delivery and top-quality parts to your facility ensure that your manufacturing facility spends time focusing on system level concerns while leaving the component-level worries to our well-versed team.

If there is a multiple part assembly, we can provide a fully delivered sub-assembly to your facility per your exact manufacturing requirements. A team of engineers will visit your facility to observe the assembly process and ensure that the manufacturing practices are preserved. The net result is more manpower at your facility while top-quality assemblies and components are delivered as expected and on time. Contact OSE for your custom inventory and assembly level solutions.